Maintaining Efficiency: Best Practices for Using Automated Assembly Machinery

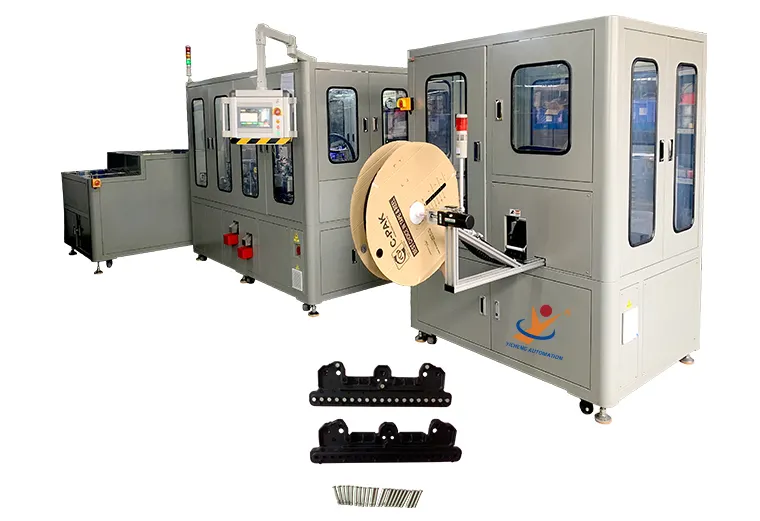

Automated assembly machinery refers to technologies designed to automate repetitive tasks, reducing human intervention and increasing speed. Types include robotic arms, conveyor systems, and assembly lines. These systems are integral to modern manufacturing, enabling continuous production and minimizing errors. Understanding the basics of each component is crucial for effective operation. For instance, robotic arms manipulate materials, conveyor systems transport products, and assembly lines coordinate tasks. Each part plays a vital role in the overall workflow.

Emphasizing Regular Maintenance

Regular maintenance is vital for the longevity and efficiency of automated machinery. Neglecting routine checks can lead to costly repairs and downtime. Tasks include lubrication, inspecting Belts and gears, and cleaning components. For example, a clogged conveyor belt can halt production, so regular inspections prevent such issues. Preventive maintenance ensures smooth operation, reducing unexpected breakdowns and saving on repair costs.

Importance of Training

Operators and maintenance staff must be well-trained to handle automated machinery safely and efficiently. Training includes hands-on workshops, simulations, and refresher courses. Skills like troubleshooting and understanding machine operation are essential. For instance, proper training can help operators diagnose issues quickly, such as a malfunctioning robotic arm, preventing production halts.

Advanced Programming and Customization

Programming and customizing machinery can enhance efficiency. Advanced programming optimizes workflows, reducing setup time. Customization allows machines to handle different product variations efficiently. For example, a company using robotic arms might customize the arm to pick specific parts, increasing productivity. Programming can also integrate with software for real-time data processing, further streamlining operations.

Technological Innovations and Upgrades

Adopting technological innovations is crucial for advancing machinery. AI integration in predictive maintenance reduces downtime by forecasting issues. Machine learning optimizes processes through data analysis. Upgrading machinery to newer models enhances efficiency and compatibility. For instance, moving from older machinery to AI-integrated systems can improve maintenance accuracy and reduce production delays.

Case Studies: Success Stories

Real-world examples highlight the benefits of best practices. A company improved productivity by 30% after implementing advanced programming, demonstrating the impact of strategic upgrades. Another reduced downtime by 20% through regular maintenance, showing the value of preventive care. These case studies underscore the effectiveness of integrating maintenance, training, and technology.

Overcoming Common Challenges

Challenges like machinery breakdowns, incompatible parts, and operator errors are common. Solutions include thorough training, preventive maintenance, and clear procedures. For example, providing detailed maintenance guidelines can help operators address issues promptly, reducing downtime. Regular training ensures operators are equipped to handle such problems, enhancing overall efficiency.

Role of Software and Data Management

Effective software systems manage machinery and analyze data for optimization. Data analytics predict maintenance needs, preventing unexpected breakdowns. For instance, software monitoring can alert before a part wears out, allowing timely replacement. This proactive approach ensures smooth production, reducing unexpected disruptions.

Future Outlook

As automation evolves, companies must adapt to new technologies. Best practices, including maintenance, training, and software integration, are key to maintaining efficiency. By embracing these strategies, manufacturers can stay competitive and enhance productivity, ensuring long-term success in a dynamic market.

In conclusion, maintaining efficiency through best practices is essential for utilizing automated assembly machinery effectively. From regular maintenance to advanced programming, integrating these strategies ensures smooth operations and competitive advantage. As technology advances, continuous adaptation will be crucial for maximizing efficiency and staying ahead in manufacturing.