Micro Fans Assembly Machine Price and Performance: The Sweet Spot

Understanding Micro Fans Assembly Machines: A Quick Guide

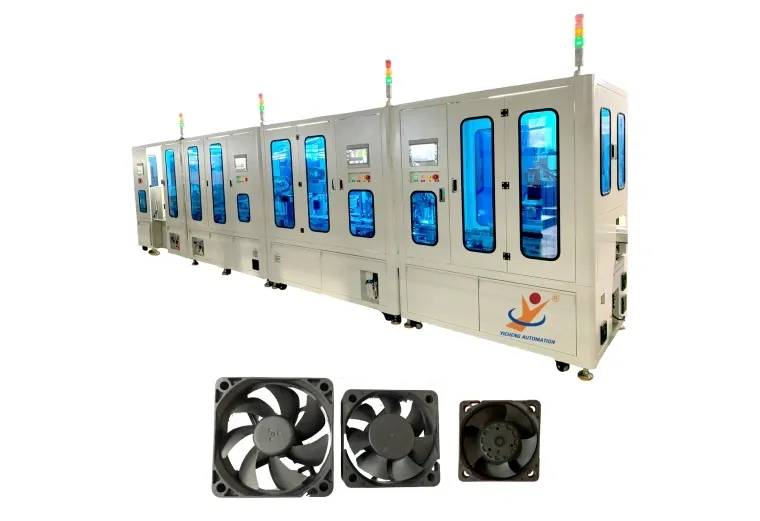

Micro fans assembly machines are specialized tools designed to manufacture compact and powerful fans. These machines are vital for industries requiring high-volume, high-quality micro fans. Common types include axial flow, centrifugal, and BLDC fans. Key features include high-speed assembly, precision alignment, and advanced automation. Modern machines often integrate AI and IoT technologies to enhance accuracy and reduce waste, making them indispensable in high-volume production environments.

For example, a precision assembly machine designed for BLDC fans can significantly reduce errors and increase production efficiency. Companies like AssemblyTech offer high-quality machines with advanced features, ensuring reliability and precision.

The Factors Influencing the Micro Fans Assembly Machine Price

Several factors determine the price of micro fans assembly machines:

- Machine Quality: High-quality machines with advanced features like 3D sensing and real-time monitoring command premium prices. These machines are reliable and efficient but come with a higher initial cost.

- Brand Reputation: Renowned brands like Robotic Solutions offer premium pricing but ensure superior build quality and customer support. Budget-friendly alternatives, such as BasicTech, provide basic functionalities at a lower cost.

- Technical Specifications: Customizable machines designed for multiple fan types are more expensive than those focused on a single type. For instance, a machine designed for high-speed BLDC fans may be more expensive due to its specialized components and advanced technology.

Performance Analysis: Enhancing Cost-Effectiveness

Performance is measured by metrics such as production speed, accuracy, and durability. High-performance machines are equipped with precision alignment systems and advanced automation, ensuring minimal errors and consistent output. However, these machines can be costly, with prices ranging from a few thousand to tens of thousands of dollars depending on the specifications. On the other hand, cost-effective machines prioritize affordability over advanced features, making them suitable for budget-conscious businesses.

A case study from a large electronics manufacturer, Tech Innovate, shows that switching to a high-performance machine resulted in a 15% increase in production efficiency and a 10% reduction in defect rates. Conversely, a small plant that opted for a basic machine experienced consistent errors and lower productivity levels.

The Ideal Sweet Spot: Finding the Perfect Balance

The sweet spot for a micro fans assembly machine is the optimal combination of price and performance that meets your specific needs. A small manufacturing plant may prioritize affordability and quick return on investment, opting for a moderately priced machine with reliable performance. Conversely, a large enterprise with high-volume production might invest in a high-performance machine that offers advanced automation and precision.

For example, a small plant with limited volume might benefit from a budget-friendly machine like BasicTech, while a large enterprise with high demand would prioritize a high-performance machine with advanced capabilities. Additionally, selecting a machine that offers customization options and after-sales support can enhance its overall value.

Comparative Studies: Machines and Their Unique Roles

Various micro fans assembly machines cater to different production environments and fan types:

- Axial Flow Fans: Machines designed for axial flow fans are often more efficient in certain applications, such as cooling in server rooms. For instance, DataCool offers specialized machines for these purposes.

- Centrifugal Fans: These machines are better suited for applications requiring high airflow, such as in HVAC systems. EcoFlow Systems provides robust machines for this specific task.

- BLDC Fans: Specialized machines for BLDC fans offer superior energy efficiency and quieter operation, making them ideal for consumer electronics. PowerFoil provides high-quality BLDC fan assembly machines.

Each machine has unique features, such as user-friendly interfaces, robust construction, or advanced control systems, catering to specific operational needs. A study by AssemblyCorp found that a custom-designed machine for small-scale production outperformed off-the-shelf options in terms of accuracy and reliability.

Tips and Tricks for Optimal Use and Cost Management

To maximize the performance and cost-effectiveness of a micro fans assembly machine, consider the following tips:

1. Maintenance: Regular maintenance schedules can extend the machine's lifespan and ensure optimal performance. Invest in parts and tools to minimize downtime. For example, TechAssembly provides maintenance kits and guides to keep your machine running smoothly.

2. Efficiency: Prioritize machines that offer energy-efficient features, such as variable speed controls and advanced automation, to reduce energy costs. A case study by GreenTech shows a 20% reduction in energy consumption with their advanced machines.

3. Purchasing: Compare quotes from multiple suppliers to ensure you're getting the best price. Negotiate terms and explore volume discounts for larger orders. Leading companies like AssemblyWorks offer competitive pricing and discount programs.

4. Training: Invest in training for operators to ensure they utilize the machine's features effectively and troubleshoot issues promptly. AssemblyPro offers comprehensive training programs for operators.

By following these tips, users can achieve the best balance between cost and performance, ensuring their micro fans assembly operations run smoothly and efficiently.

Navigate the Market for Optimal Micro Fans Assembly

Selecting the right micro fans assembly machine is a critical decision that impacts production efficiency and cost savings. The sweet spot lies in balancing price and performance to meet your specific business needs. By evaluating factors such as machine features, performance metrics, and cost, businesses can make informed decisions that enhance productivity and profitability. Whether you're a small manufacturing plant or a large enterprise, understanding the trade-offs between different machines will help you achieve the optimal balance for your operations. In the ever-evolving market of micro fans assembly, staying ahead requires not only selecting the right machine but also maintaining a strategic approach to its use and maintenance.