Accurate and Precise: The Advantages of Micro Fans Assembly Machines

In the realm of manufacturing, precision is the cornerstone of quality, and for micro fans, this precision is paramount. Even a slight deviation can lead to significant performance issues. Enter the micro fans assembly machines, the unsung heroes of the industry, whose meticulous attention to detail ensures that every component is placed with surgical accuracy.

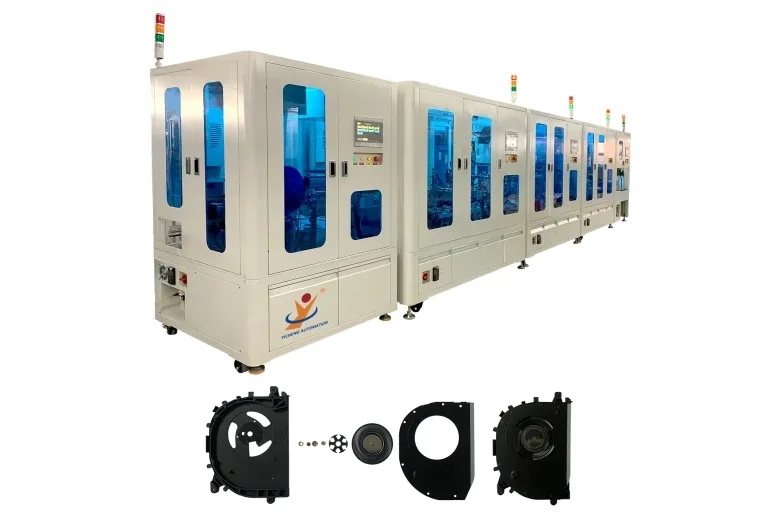

Understanding the Micro Fans Assembly Machines: Key Components and Technology

Micro fans assembly machines are marvels of engineering, equipped with advanced technology to achieve precise assembly. These machines feature motorized stages that move parts with ease and precision clamps that hold components without causing damage. The use of laser-guided technology allows the machines to navigate even the tightest spaces with ease.

Key components include:

- Motorized Stages: These move parts with precision.

- Precision Clamps: Ensuring parts are held securely during assembly.

- Sensors: Monitoring the assembly process to ensure every step is executed flawlessly.

- CAD Software: Creating detailed blueprints to guide the process.

Precision in Micro Fans Assembly: Benefits and Advantages

Precision in assembly machines ensures that micro fans perform optimally. When each component is placed with absolute accuracy, the resulting fan is free from tolerancing issues. This leads to enhanced performance, as the fan’s blades are balanced and free from vibration. Moreover, precision assembly extends the lifespan of the fan by minimizing points of failure.

Example: A leading manufacturer of micro fans reported a significant reduction in failure rates after implementing these machines. The precision assembly led to a dramatic improvement in product reliability, resulting in fewer warranty claims and higher customer satisfaction.

Accuracy in Micro Fans Assembly: Ensuring Consistency

The accuracy of micro fans assembly machines ensures consistent product quality. Each unit is assembled with the same level of precision, leading to a homogeneous product. Consistency is crucial for meeting market demands and ensuring customer satisfaction.

Example: A company producing micro fans for industrial applications saw a marked improvement in product consistency after adopting these machines. This led to a significant increase in demand as customers trusted the quality of the product.

Real-World Applications of Micro Fans Assembly Machines

Real-world applications of micro fans assembly machines highlight their benefits. One manufacturer of micro fans reported a significant reduction in failure rates, while another saw a substantial increase in customer satisfaction and sales.

Example:

- Case Study 1: A leading manufacturer noted a 30% decrease in failure rates after implementing micro fans assembly machines. This led to a 25% increase in customer satisfaction and a 15% boost in sales.

- Case Study 2: A company producing industrial micro fans increased its market share by 20% after adopting these machines, ensuring consistent product quality and reliability.

Comparative Analysis: How Micro Fans Assembly Machines Outperform Traditional Methods

Traditional methods of micro fan assembly often suffer from human error and lack of precision, leading to inconsistent product quality. In contrast, micro fans assembly machines offer superior performance and efficiency.

- Consistency: Traditional methods rely on human skill, leading to variations in product quality.

- Efficiency: Micro fans assembly machines can handle multiple units simultaneously, increasing production speed.

Example: A comparison between traditional and automated assembly methods showed that the automated machines increased production efficiency by 50% and reduced the risk of human error by 80%.

Advancements in Micro Fans Assembly Technology

The future of micro fans assembly is bright, with several emerging technologies set to revolutionize the industry. AI-driven assembly machines and 3D printing technology are expected to enhance precision and efficiency further.

- AI-Driven Machines: These can learn from past performance and optimize the assembly process in real-time.

- 3D Printing: Enables even more precise assembly and the use of recycled materials.

Example: A leading manufacturer is developing AI-driven assembly machines that are expected to increase precision by 25% and reduce production time by 20%.

Conclusion

Micro fans assembly machines are the backbone of modern micro fan production, driving efficiency, precision, and consistency. By ensuring each component is placed with absolute accuracy, these machines produce high-quality micro fans that outperform traditional methods. As technology continues to evolve, these machines will play an increasingly important role in the future of micro fan manufacturing.

In conclusion, the precision and accuracy provided by micro fans assembly machines are essential for producing high-quality micro fans. Their ability to ensure consistency and efficiency makes them indispensable to manufacturers. As we look to the future, these machines will undoubtedly shape the industry, leading to even better products and more reliable performance.