Electronics Assembly Machine Manufacturer - - Yicheng-2

Company Advantages

· Yicheng electronics assembly machine manufacturer is designed and crafted by a team of experts following the international standards.

· It outperforms other competitors in the market in all aspects, such as quality, performance, durability.

· Dongguan Yicheng Automation Equipment Co.,Ltd. has complete quality guarantee system and wins the trust of customers.

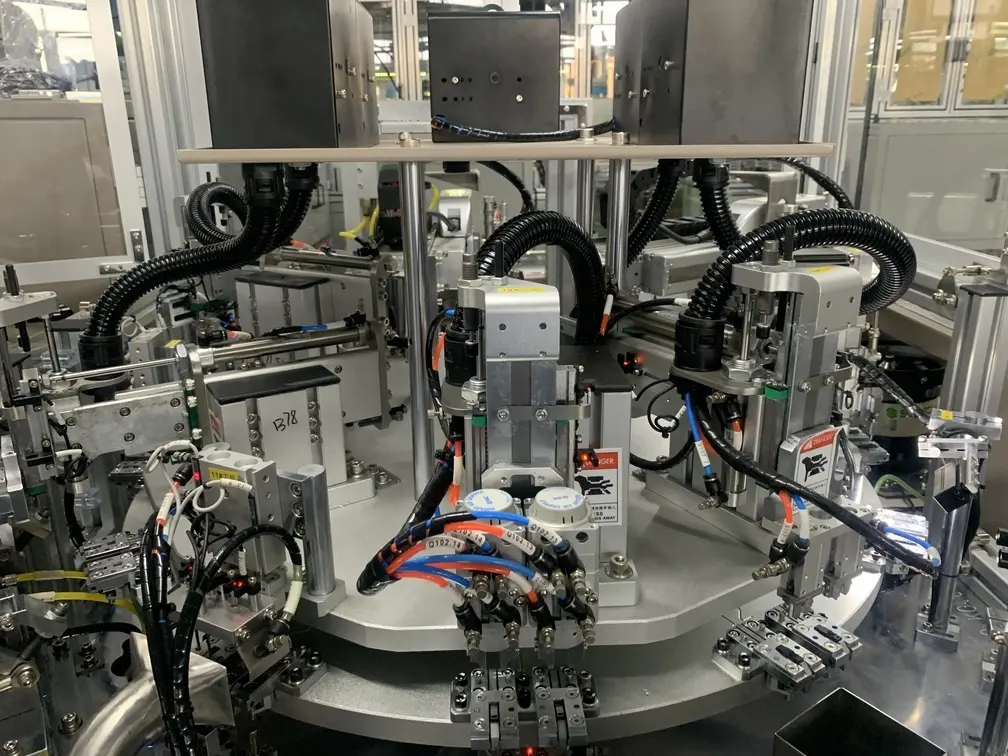

| Components Qty | 4 parts |

| Cycle Time | 20-25 pcs/min |

| OEE | 95% |

First Pass Yield | 99.5% |

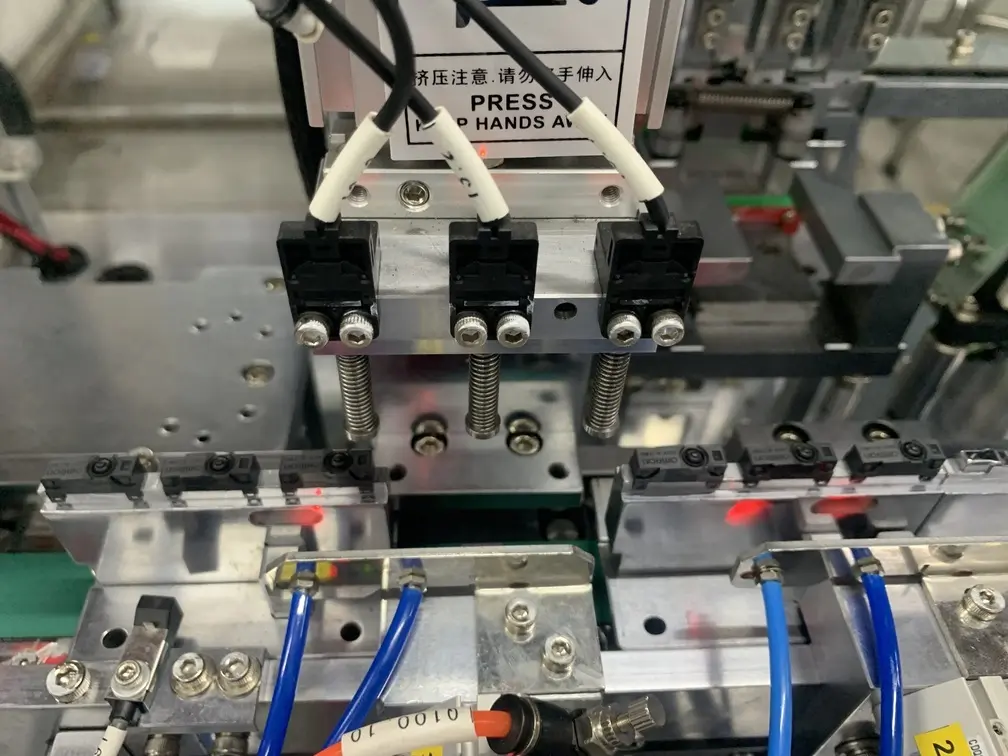

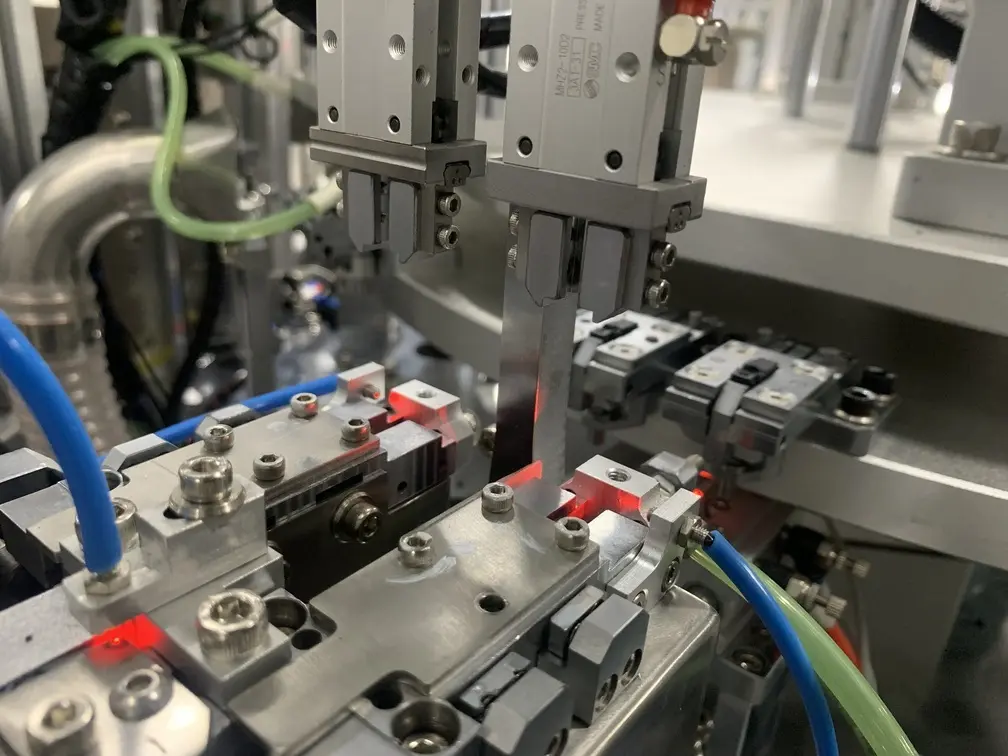

Standard Parts Brand | Panasonic, Mitsubishi, SMC, Keyence, Omron |

Requested Operators | 1 |

Certificate | CE |

Company Features

· Dongguan Yicheng Automation Equipment Co.,Ltd. enjoys a high prestige among the customers at electronics assembly machine manufacturer field.

· We have a strong customer base all around the world because we have been sincerely working with our customers to develop, design, and manufacture electronics assembly machine manufacturer based on their requirements. Our modern factory is equipped with highly advanced production facilities under the principles of zero pollution and cost efficiency. The factory owns state-of-the-art large-size production machines in the electronics assembly machine manufacturer industry. These machines offer support for daily production needs, including product developing, designing, production, and packaging.

· We are open to new ways of thinking and doing things, in order to create new possibilities for customers. We will always respond to unexpected challenges in a bold way to capture global strengths and achieve operational excellence.

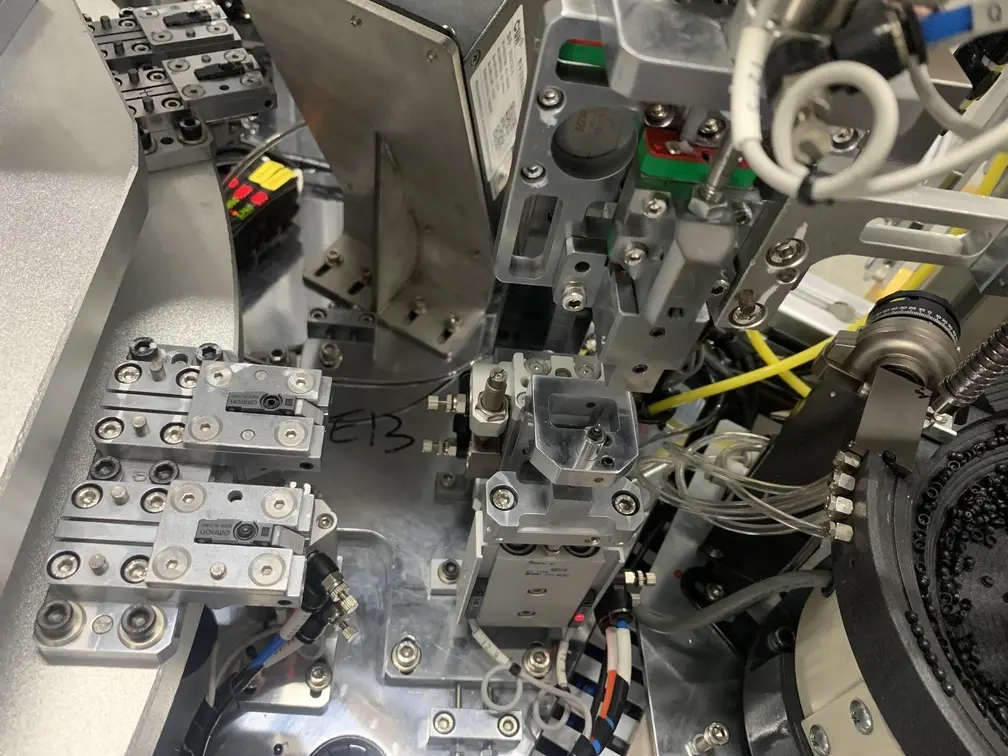

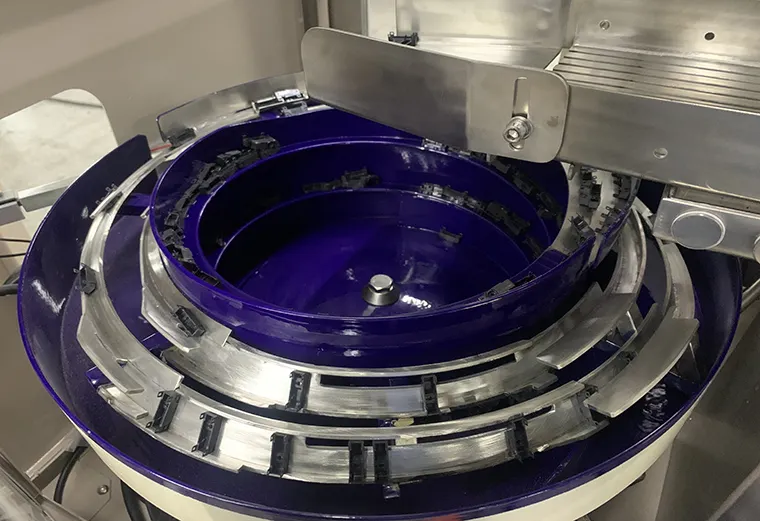

Product Details

The electronics assembly machine manufacturer we produce are able to stand up to the details.

Enterprise Advantages

Yicheng Automation established a professional talents team. They have strong R&D capabilities and great technical abilities.

Yicheng Automation is able to provide professional and thoughtful services for consumers for we have various service outlets in the country.

Yicheng Automation runs a professional, standardized and scale business. We take 'excellence and innovation, diligence, rigor and honesty' as our enterprise spirit. Moreover, we highly value sincerity, responsibility and environmental protection. Based on the firm belief of development, we take the initiative to assume social responsibilities while emphasizing economic benefits. We are committed to becoming an excellent manufacturer in the industry.

Through the rapid development for years, Yicheng Automation has now developed into a modern enterprise with the scientific management system and superb processing technology.

At present, Yicheng Automation's business range covers multiple regions in the country. We also strive to open up overseas market based on the mature domestic market.

After we complete the assembly and debugging of the equipment, we will inspect and select appropriate packaging materials to protect the equipment from shock, moisture, and fixation.

Make sure the equipment reaches its destination in good condition.

● On site installation, debugging, training and mass production follow up.

● 1 year Warranty from date of shipment, lifetime maintenance service.

● Response any defects claims within 4 hours for mainland customers.

● 12 hours for overseas customers by telephone or mail.

● Supply remote services by smart glass, team viewer, Teams and camera.

1. The technical training described below is free technical training, and no additional fees are charged. The technical training consists of the project's on site general manager, mechanical engineer and electrical engineer, who are responsible for implementing the entire training plan.

2. The whole process of installation from the installation to the commissioning is carried out by the expert group and the production technology, equipment management and production operators designated by the customer. At the same time, the expert group is responsible for technical guidance to the customer's technical staff throughout the implementation process. Training with technical points, including:

a. Equipment system principle and operation method, maintenance.

b. Equipment operation and debugging, parameter setting.

c. Operation and application of the software.

d. Operating procedures and precautions for the equipment.

e. Safety protection measures for various action agencies.

f. Maintenance of electrical systems and mechanical parts.

g. How to make correct judgment, analysis and how to troubleshoot when the equipment fails.

h. Solutions to possible dangerous situations.