Automatic Screw Locking Machine by Yicheng

Company Advantages

· Yicheng automatic screw locking machine is manufactured with raw materials that meet the regulatory specification.

· The product meets the highest quality and safety standards.

· Our mission in Dongguan Yicheng Automation Equipment Co.,Ltd. is to satisfy our customers not only in quality but also in service.

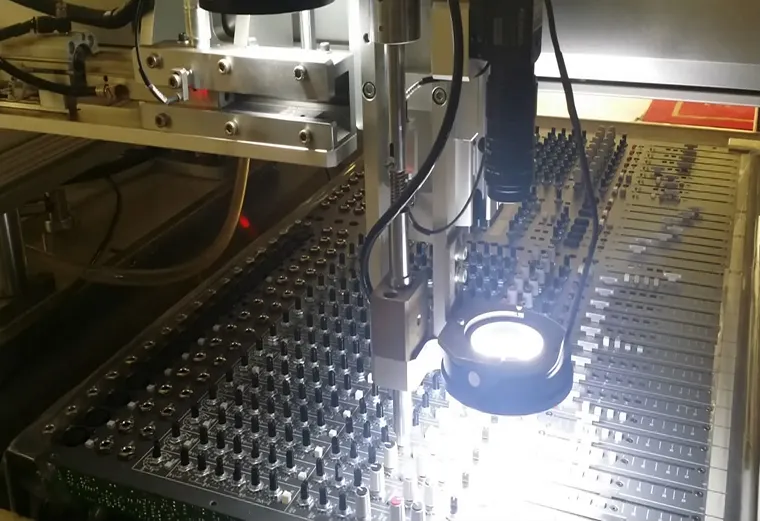

| Cycle Time | 720-1080 pcs/h |

| Dimensions | 2.5m(L)*1.2m(W)*1.8m(H) |

| Weight | About 1500kg |

| OEE | 85% |

First Pass Yield | 99% |

Standard Parts Brand | Panasonic, Mitsubishi, SMC, Keyence, Omron |

Requested Operators | 1 |

Certificate | CE |

Company Features

· Relying on years of experience in developing and manufacturing of automatic screw locking machine, Dongguan Yicheng Automation Equipment Co.,Ltd. has taken up most part of the market in domestic.

· We have won over many customers all around the world thanks to our complete sales-service system and our customer service team who strives to provide the most intimate service for customers. As the demands for the products increase globally, we deeply aware that strong innovation capacity is as critical as high-quality products. Fortunately, we have a professional R&D team which enables us to provide innovative solutions to our customers for various customized products. Those professionals help our products stand out of the market. Based on the outstanding end-to-end service support, we have been replete with a large customer base. The customers from around the world have been cooperating with us for years since the first order.

· We adhere to the business philosophy of 'honesty, pragmatism, cooperation and win-win'. We take customers' concerns into consideration and spare no effort to offer targeted product solutions for them.

Product Comparison

Compared with similar products, the automatic screw locking machine of Yicheng Automation is more strict in the selection of raw materials. The specific aspects are as follows.

Enterprise Advantages

Our company has a strong team of professional technology and R&D personnel. We also gather a skilled management team and they work hard and are willing to make breakthrough. All that brings a better future for our company.

With a complete service system, Yicheng Automation is dedicated to providing consumers with comprehensive and thoughtful services.

Yicheng Automation always pays attention to customers and sincere services. We are committed to providing high-quality products and comprehensive services for numerous customers. We aim to become a renowned and leading enterprise in the domestic market.

Our company was established in After years of hard work, we have accumulated a lot of industry experience. Moreover, we are highly recognized by the industry.

Our Assembly Machine,Automated Equipment,Automatic Assembly Machine we produce are favored by many foreign customers and the export destination is mainly in most countries and regions in Southeast Asia, South Asia and Africa.

After we complete the assembly and debugging of the equipment, we will inspect and select appropriate packaging materials to protect the equipment from shock, moisture, and fixation.

Make sure the equipment reaches its destination in good condition.

● On site installation, debugging, training and mass production follow up.

● 1 year Warranty from date of shipment, lifetime maintenance service.

● Response any defects claims within 4 hours for mainland customers.

● 12 hours for overseas customers by telephone or mail.

● Supply remote services by smart glass, team viewer, Teams and camera.

1. The technical training described below is free technical training, and no additional fees are charged. The technical training consists of the project's on site general manager, mechanical engineer and electrical engineer, who are responsible for implementing the entire training plan.

2. The whole process of installation from the installation to the commissioning is carried out by the expert group and the production technology, equipment management and production operators designated by the customer. At the same time, the expert group is responsible for technical guidance to the customer's technical staff throughout the implementation process. Training with technical points, including:

a. Equipment system principle and operation method, maintenance.

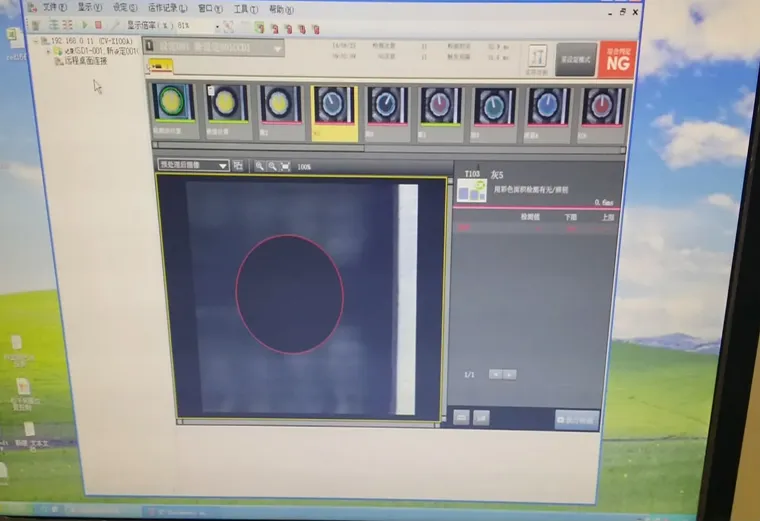

b. Equipment operation and debugging, parameter setting.

c. Operation and application of the software.

d. Operating procedures and precautions for the equipment.

e. Safety protection measures for various action agencies.

f. Maintenance of electrical systems and mechanical parts.

g. How to make correct judgment, analysis and how to troubleshoot when the equipment fails.

h. Solutions to possible dangerous situations.