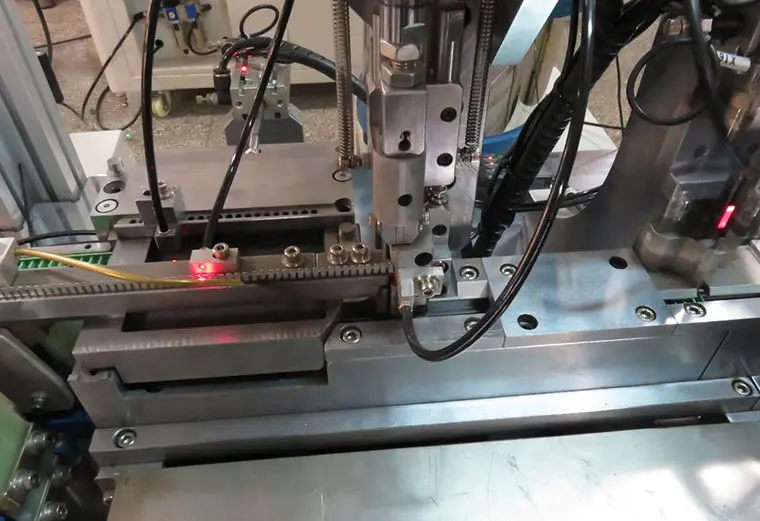

Assembly Machines - - Yicheng-1

| Components Qty | 4 parts |

| Cycle Time | 1200pcs/hour |

| OEE | 90% |

First Pass Yield | 99.5% |

Standard Parts Brand | Panasonic, Mitsubishi, SMC, Keyence, Omron |

Requested Operators | 1 |

Certificate | CE |

Company Advantages

· There is a fact that the function of assembly machines is well-designed to match the needs of the products.

· Before delivery, the product has to be inspected strictly to ensure that it is of high quality in every aspect as such as performance, usability, and so on.

· As long as our customers have questions about our assembly machines, Dongguan Yicheng Automation Equipment Co.,Ltd. will make timely response.

Company Features

· Dongguan Yicheng Automation Equipment Co.,Ltd. has been focusing on producing assembly machines for years. Leveraging unrivaled expertise, we are one of the most sought-after manufacturers.

· Our production is very convenient for logistics. Located near local ports and highways, transportation lines and distances are shorter, faster and cheaper.

· The goal of Dongguan Yicheng Automation Equipment Co.,Ltd. would be the leader among the international brands. Check it!

Application of the Product

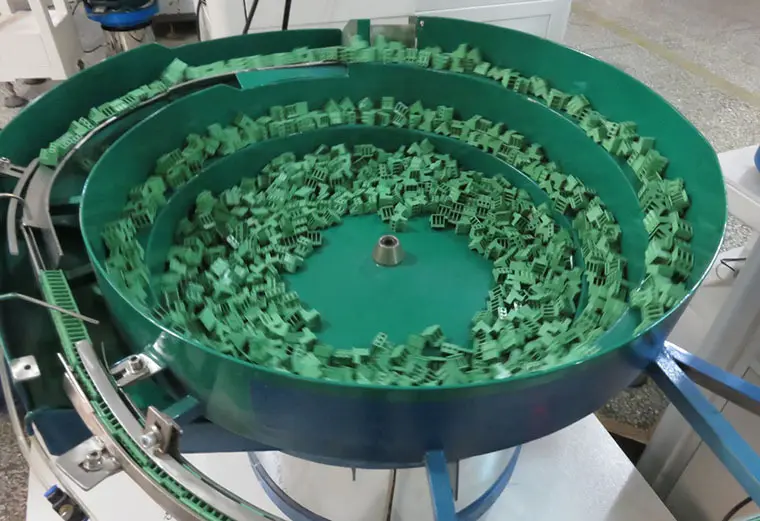

Yicheng Automation's assembly machines is widely used in various scenes.

Yicheng Automation insists on providing customers with one-stop and complete solution from the customer's perspective.

After we complete the assembly and debugging of the equipment, we will inspect and select appropriate packaging materials to protect the equipment from shock, moisture, and fixation.

Make sure the equipment reaches its destination in good condition.

● On site installation, debugging, training and mass production follow up.

● 1 year Warranty from date of shipment, lifetime maintenance service.

● Response any defects claims within 4 hours for mainland customers.

● 12 hours for overseas customers by telephone or mail.

● Supply remote services by smart glass, team viewer, Teams and camera.

1. The technical training described below is free technical training, and no additional fees are charged. The technical training consists of the project's on site general manager, mechanical engineer and electrical engineer, who are responsible for implementing the entire training plan.

2. The whole process of installation from the installation to the commissioning is carried out by the expert group and the production technology, equipment management and production operators designated by the customer. At the same time, the expert group is responsible for technical guidance to the customer's technical staff throughout the implementation process. Training with technical points, including:

a. Equipment system principle and operation method, maintenance.

b. Equipment operation and debugging, parameter setting.

c. Operation and application of the software.

d. Operating procedures and precautions for the equipment.

e. Safety protection measures for various action agencies.

f. Maintenance of electrical systems and mechanical parts.

g. How to make correct judgment, analysis and how to troubleshoot when the equipment fails.

h. Solutions to possible dangerous situations.